Hose clamps are a critical consideration whenever you think about your car’s maintenance because the fluids that are transmitted through those hoses run the car. The fuel hose feeds gasoline to the engine as the radiator hose delivers coolant. The power steering hose on the other hand facilitates lubrication of the steering system. These are just the tip of the iceberg and there are plenty more hoses to talk about.

Different types of hose clamps have different capabilities and it is good to know the differences so you can decide which ones best suit your specific hoses the next time you conduct maintenance on your automobile. This article breaks down the most common types of hose clamps, along with their strengths and weaknesses. You should be able to discern which clamp goes where, by the time you are done so that your hoses don’t fall off the barb or start leaking from excessive pressure.

The Different Types of Hose Clamps

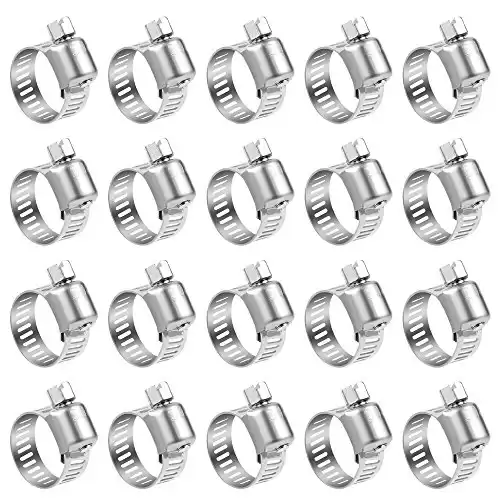

1. Screw Hose Clamps / Band Hose Clamps

They are also known as worm gear hose clamps or worm drive clamps after their fastening mechanism, and in some parts (mostly in the UK) as Jubilee clamps after the well-known brand of screw hose clamps.

These clamps have two parts:

- The band that will encircle the hose and secure it in place, which usually has a screw thread pattern cut or pressed onto it.

- A captive screw that is attached to one end of the band will be used to adjust the tightness of the band around the hose.

The band is wrapped around the hose, slotting the end without the captive screw into a narrow slot that is left in between the captive screw and the other end of the band (kind of like wearing a watch). The hose is then pushed onto its fitting until it reaches the desired position before it is fastened. The captive screw is now turned and performs the role of a worm drive (from where the clamp gets the name), pulling at the threads of the band and making it tighter against the hose. The hose will in turn tighten around the fitting, sealing the joint so that the fluid can’t leak.

All you need to do to loosen the hose when servicing the car or replacing it is to turn the screw in the opposite direction. The best band clamps are made of galvanized or stainless steel and are rust-resistant

Shortcomings of a Band Clamp

- Their adjustment slots can fray the hose, strip it, or cut into it.

- They also can’t compensate for changes in the dimensions of the hose when it shrinks and may lead to leaks in the future when the tension becomes inadequate.

- It is sometimes hard to access the screws with your screwdriver or nut driver, depending on the placement of the hose

2. Spring Hose Clamps / Constant Tension Hose Clamps

A spring hose clamp is made of a strip of spring steel which has been rolled to form rings that are slid on top of the hose to hold it in place. One side of the steel strip is tapered to form a narrow protrusion while the other side ends in two protrusions that resemble a fork. The protruding tips intermesh when the spring steel is rolled into a ring and they are bent slightly outwards facing opposite sides to facilitate handling.

To clamp the hose, the extended bent tips are pinched and pressed toward each other (using a set of pliers or any suitable hand tool to counter the high tensile strength), expanding the diameter of the ring in the process. The ring is then slid onto the hose and pushed back beyond the part of the hose that will go on the barb of the fitting. This allows the hose to be fitted on the barb and pushed in. The clamp is pinched again and slid onto the portion of the hose that is covering the barb and then released. The high yield strength of the spring steel will have the ring returning to its original shape and it will clasp the hose tightly, pressing it against the barb and sealing the joint.

These clamps offer an option for clamping hoses in awkward places where the angles are inaccessible for the tightening tools required by a screw hose clamp.

There is a reason they are also called constant tension clamps; they will apply constant tension on the hose regardless of its prevailing condition. They keep delivering even after the state of the hose deteriorates from the elements. Hoses might swell, harden, soften and compromise their structural rigidity as they age. The high yield strength of the spring steel strips is constantly in play, and it will be unyielding despite the changes in dimensions.

3. Wire Hose Clamps

These employ a similar system to the screw hose clamps but the band is replaced with a heavy-duty wire (or wires). The wire is bent to a U-shape then forged into a ring with the ends overlapping and then bent outwards. A captive nut is attached to one end and a captive screw on the other.

As you tighten the screw, it pushes the overlapping ends of the wire away from each other. The more they move apart from each other, the tighter the noose on the hose becomes, pressing it harder against the barb. This pressure seals the joint and prevents the fluids from escaping.

4. Ear Hose Clamps

These types of hose clamps also feature a metallic band (rust-resistant galvanized or stainless steel are the best) on which one or more protrusions, referred to as ears, are formed to serve as closing elements. The sides of the ears grip together to tighten the band around the hose and hold it in place.

The clamp is slid onto the hose on the side that is to be connected to the fitting while still loose. The hose is then slid onto the fitting’s barb where it’s supposed to be secured with the loose clamp on it. Using a pincer or any workable tool, the base of the ears is closed and they interlock, deforming permanently. The resulting pressure on the hose against the barb makes the joint solid.

This option has no room for error because once the ears have interlocked, they deform completely and can’t be adjusted. If the size of the chosen hose clamp is wrong, the ears won’t close completely and the joint will be compromised. You are forced to discard the hose clamp and get a replacement. There are however ear clamps with dimples that replicate the spring effect and can allow a bit of adjustment with the hose’s expansions and contractions, but they are hardly as consistent a spring clamp.

5. T-Bolt Hose Clamps / Racing Hose Clamps

This is the high-end option of automobile hose clamps. They are designed for the high-performance, high-pressure conditions of race car driving like turbo pressure hoses and coolant hoses for powerful engines. They provide 360° of tension on the hose, with minimal chances of leakage, and are more rugged than every other hose clamp mentioned in this article.

They comprise a band that goes all the way around the hose with the ends overlapping so there are no weak points. The band is fastened by a T-bolt that is built on the outside and a nut that applies uniform pressure on the hose.

They come at a premium and are usually not the stock option for car manufacturers’ factory installation.

Our Take

It is not cost-effective to use high-end hose clamps for all the hoses in your car, neither is it necessary or even possible. Some hoses like the steering fluid hoses will rarely have sufficient pressure to justify such an arsenal. Many cars run efficiently for years without a single T-bolt hose clamp. There are also confined spaces where they will be hard to fix without dismantling the whole car.

That being said, these types of hose clamps will bear the brunt of high-pressure driving better than the others. The right hose clamp selection for a particular hose should be based on the pressure the hose has to endure to get value for your money. Remember that you can have different types of hose clamps on the same car.