Are you shopping for an air compressor?

Please wait!

Do not purchase before reading this guide, which will definitely lead you to the best 60-gallon air compressor. This is a huge investment and it is only logical to ensure that you get the right one.

With an air compressor, you will be able to complete a couple of tasks as it comes with loads of benefits.

There are different sizes and models on the market and this may make it difficult for you to identify the right one.

In this guide, I will show you, in detail and supporting reviews how to pick the right air compressor. Stay with me and at the end, you will make an informed purchase decision.

Top Air Compressor

- Best 5hp Gallon Compressor – stronguQuincy QT-54 Splash/u/strong

- Best 60 Gallon For Home Garages – stronguPuma Industries Air Compressor/u/strong

- Best Quiet 60 Gallon Compressor – stronguCalifornia CAT-60040CAD/u/strong

- Best For Electric Air Compressor – stronguDeWalt DXCMV5076055 60 gallon/u/strong

- Most Powerful Air Compressor- stronguEmax18 HP Gas Air Compressor/u/strong

- Best Two-Stage Air Compressor – stronguIndustrial Air IV5076055/u/strong

- Best Single Stage Air Compressor – stronguPowerMateVx PLA3706056/u/strong

Best 60 Gallon Air Compressor Reviews 2022

Now that you are already aware of the benefits of a 60-gallon air compressor, you must be ready to purchase one. Here are reviews of our top pick and this will help in your final purchase decision.

1. Quincy QT-54 Splash Reciprocating Air Compressor – Best 5hp

One of the best features of this model is the 5 HP motor, which gives it plenty of power. This will enhance the performance on any task that is at hand. It has been made to last, as it is made from cast iron. It is made in the US and is best rated for industrial use.

The life of the pump on this model is rated to last up to 30,000 hours, which is quite impressive. There is a finned tube intercooler, which will extend the lifespan of the valve. The aluminum head is ideal for heat dissipation. The head has a rugged design to aid its functionality.

As for safety, the Quincy comes with protection from low oil levels and also has a capacitor start motor. This is an ideal compressor as it operates on minimal vibration. It is convenient as it produces more compressed air, at very low horsepower.

Pros

- Durable model

- Has the protection from the low oil level

- Minimal vibration

- Long-lasting pump

- 5 HP motor with exceptional power

- Capacitor start motor equipped with a thermal overload

Cons

- It is rather too loud

- Expensive in price compared to similar models

2. SS3L3 3 HP 60 Gallon Air Compressor – Best For The Money

This is another option for you if you want to find an ideal 60-gallon air compressor. This is a 230-volt single-phase compressor, with adequate power to handle many tasks.

It has a 3 HP motor, which is powerful enough to handle all manner of applications, even the most demanding ones. It has a high-pressure operation of up to 135 PSI

This model is made of cast iron, which makes it durable. It also has a long-lasting extended pump life, which gives you over 5,000 hours of consistent use.

There is an automatic start/stop pressure switch control, for easier operation. It is pre-wired from the factory and making it ready for use on delivery.

The manual overload protection of the motor enhances the safety of the motor. The belt guard is enclosed and this guarantees constant protection. It has an all-season select synthetic lubricant, for a reliable operation.

This is a worthwhile investment as the manufacturer has been in business for over a century.

Pros

- The model produces minimal noise levels

- It comes with manual overload protection for the motor

- Capable to handle industrial applications

- Long-lasting pump able to deliver 5000 hours of use

Cons

- Seems to overheat easily

- The pressure switch is poorly constructed

3. Industrial Air IV5076055 60 gallon Air Compressior – For Two Stage

Here is yet another product that is designed for the exclusive use of heavy-duty applications. This is a model with solid construction and is meant to work even in the toughest conditions.

It is made of cast iron and fitted with a twin cylinder. There is a two-stage crankcase made of cast iron, which is thermally stable.

The oil-lubricated pump is durable will run consistently for a longer period. There are ball bearings are similar to automotive, which are known to enhance the movement of this model.

It comes with durable Swedish reed valves, which are made of stainless steel. The large capacity gallon will give you more compressed air, at a very low HP.

The oil fill is easy to access and there is also a balanced flywheel made of cast iron. The oil sight glass will help you in monitoring the oil levels.

The maximum pressure rating is 175 PSI and has 230-volt power, which gives you maximum performance. The pressure gauge and power switch are additional features that make this model user-friendly.

Pros

- Durable cast iron one-piece crankcase

- Easy access to the oil fill

- Has an on/off switch and pressure gauge

- Thermal overload included

- Perfect for heavy-duty use

Cons

- The motor is rather flimsy

- Seems to overheat

- Does not come with an electrical cord

4. Puma Industries/Commercial Air Compressor – Best For Home Garages

This is a commercial and professional air compressor and is loaded with versatile features. It is a single belt drive series, which helps in the smooth operation of the machine.

The 3 HP motor is ideal for this model and it has a PSI rating of 135. It runs on 230 volts and this makes it an excellent option to consider.

The single-stage cast iron pump is solid and long-lasting. It is oil lubricated and has a large 60-gallon vertical tank. The single-phase induction motor has overload protection to enhance the safety of the air compressor.

This is a portable model and it comes with a built-in pressure regulator and also a coupler for pressure control of the outlet air.

The mobility of the air compressor is well-thought-out as it has steel wheels that have a ball bearing. The tires are not flat and this makes it possible to move them on any terrain. The vertical design makes it ideal for even smaller spaces.

Pros

- Steel wheels with ball-bearing for mobility

- Powerful 3 HP motor, with overload protection

- Durable pump

- Practical vertical design

- Oil-lubricated

Cons

- Lacks the capacity to handle demanding applications

5. Industrial Air ILA3606056 – Cheapest 60 Gallon Air Compressor

This is one of the products from Industrial Air, which are designed for heavy-duty use. This model comes with additional components that will aid its functionality. It is durable and will withstand the toughest conditions.

It is made of cast iron and comes with a twin cylinder, making it ideal for most mechanical applications.

The pump on this model is oil-lubricated to facilitate smooth functionality. The cast-iron cylinder body is thermally stable to enhance the safety of the air compressor.

There is aluminum- made head and a valve plate, which make this air compressor versatile. There are ball bearings, which are styled as those on automotive enhance the overall use of the machine.

The reed valves are made of stainless steel which makes them quite durable. With the large 60 gallon tank, you will run the machine and get compressed air for a longer time.

This is a 240 volts unit and it is with a rating of 155 PSI, for maximum pressure. It comes loaded with a pressure gauge and a power switch.

Pros

- User-friendly model

- Has the capacity to handle industrial tasks

- Comes with a thermal overload protection

- Durable model, made of cast iron

Cons

- Records a very high running temperature

- You have to buy the electrical cord independently

6. PowerMateVx PLA3706056 60-Gallon – Single Stage Vertical Cast Iron Air Compressor

The PowerMate is a single vertical cast iron air compressor and is the best compressor for DIYers and commercial users alike. It has a pump that is lubricated with oil model and is long-lasting.

The solid cast iron construction is what makes it a worthwhile investment. This is a great machine to have and will make your work easier.

It has a one-piece crankcase constructed with cast iron, which also expands the functional life of the pump. The cylinder body is also made of cast iron, which is solid and it is thermally stable.

The other essential features include the valve plate and head made of aluminum, and also ball bearings. The reed valves are durable and made of stainless steel.

The oil fill is easily accessible and it is also equipped with cast iron and a well-balanced flywheel. With the sight glass, you will be able to tell when you need to refill the oil.

There is an induction motor with 240 volts that is made to give you the best performance and has a pressure of 155 PSI Max.

Pros

- Durable cylinder body and pump

- 155 PSI pressure rating

- Easy to use

- Cast-iron double cylinder pump

- Thermally stabilized

- Has overload protection

Cons

- Lacks a regulator

- Too noise

- Seems to consume too much power

7. California Air Tools CAT-60040CAD 60 Gal Compressor – Best For Quiet

This brand is very flexible for customer service because it has many special functions which you usually do not find in general compressors with noiseless arrangements with 75 decibels. In addition, their external parts are decorated with steel.

You do not have to give effort to maintaining California Air Tools 60 gallon compressors. This is powered by 2HP running motors, which provide an upgraded performance. It can control 10.60 CFM at 90PSI and also 12.60 CFM at 40 PSI.

Magnetic starters are not required for these compressors and give extra protection from overheating. With all these features, it can be considered a well-designed gadget and has switching on and off options, making it easy for users to manage the temperatures and pressure.

Pros:

- Not required oil for pumping

- Provides long duty cycles and can work for long hours in a day.

- Provides warranty cards and is durable.

- Easy to maintain with low costs

- Lightweight

Cons:

- It is not designed for indoor uses.

8. DeWalk DXCMV507655 Two-Stage Air Compressors – Best For Electric

This can be ranked as the third-best air compressor because of its outstanding quality. It is powered by 175 PSI and can operate many options for air tools. However, it is designed for industrial purposes, not suitable for indoor use because it is enormous.

As it is made for industrial purposes, the intake filter of these air compressors is robust and secured. It has a low pump RPM with four extensions. In addition, it has well-equipped motor power, which displays the level of control of the engine that works.

The better the motor power, the more air compressors will work. Storage areas are pretty big.

Pros:

- Offers cooler running pump

- Protects the motor from voltage fluctuations

- Large space

Cons:

- As it is a two-stage air compressor, it is more expensive than single-stage air compressors.

9. EMAX 18HP Gas Air Compressors – Most Powerful

This is not any less than other air compressors. On the contrary, this is one of the powerful air compressors whose power can be generated for 50000 hours. Furthermore, I would say it is one of the most quality 18HP air compressors in the current market.

It has concentric valves that give proper airflow. The pumping system of these air compressors is 50% better than other air compressors because of its well-built, unique ideas and 34 CFM. This also provides efficient fuel services.

The unique aspect of this gas compressor is its durability. As it has a superb engine that can process fuel very efficiently, that holds the key to the longevity of the compressor core.

Pros:

- It does not become too warm like other air compressors at the time of operations. So it can also be considered as the compressors that can remain cool and stable

- Noiseless

Cons:

- There is no regulator

Buying Guide For Best 60 Gallon Air Compressor

With numerous products on the market, the process of finding the right choice can be quite demanding. Here are some of the factors that you should consider to find the best 60-gallon air compressor.

Mobility

Generally, the 60-gallon air compressor is rather heavy. Therefore, you need to consider the extra features that are included to facilitate mobility. A model with wheels and handles will be easy to move around.

Tool to Power

To make the right choice, you need to bear in mind the specific tools that you wish to power with the compressor. All the SCFM and PSI information of the tools need to be factored to make a sound decision.

Frequency of Use

While this may seem to be a simple thing, it really matters how often you will be using the air compressor. For those who plan to use it occasionally, it may not be the same as those who use it several times in a day. It is best to pick a model that exceeds your usage needs.

Noise Levels

Most modern air compressors are significantly quieter. It is imperative to check the decibels so that you can find the quietest 60 gallon air compressor.

Place of Use

Air compressors emit fumes and as such, they are not ideal for indoor use. They are quite useful for outdoor purposes, especially in places where there is no electricity.

Work Place Conditions

Consider the conditions of the workplace. This will help you in determining the length of the hose from the tank and other essential details. It is also important to consider the length of the electrical cord and the distance to the power source.

Price

Last, but not least, check the price range. Be sure to compare a number of models in the same price range and check all the features. Pick the best model for the money.

Types of Air Compressors

One of the most fundamental things that you need to understand when considering to buy an air compressor are the types available. With this understanding, it becomes easier to pick a model that serves your needs, in the best way.

Generally, there are 2 main types of air compressors:

1. Portable Air Compressors

These are ideal for home-based tasks and they have the advantage of being compact and portable. In most cases, they will have wheels to enhance mobility from one place to another. There a couple of options in this category, including pancake, wheelbarrow, hotdog and twin-stack.

2. Stationary Air Compressors

These are quite large and specifically designed for the most demanding applications. With this type of air compressor, they will be used for industrial or commercial tasks and as such are preferred by experts. Most of them come with a vertical design to economize on space usage.

Why Get 60 Gallon Air Compressor?

- It gives you plenty of compression power to handle heady duty tools

- Makes it easier to handle pneumatic tools as it makes them lighter

- Air compressors are far much safer than electrical tools, making them ideal for most work environments

- These are cheaper than the battery or electrical tools

- These are large tools and you can power up several tools simultaneously, which saves your energy consumption

- With the large tank, the tools will run for a longer time, and this will be at a consistent CFM

How To Use An Air Compressor

It is one thing to own an air compressor and a different thing to use it properly. Even if you have the best model on the market and have no idea on how to use it, then it is will be futile. Each model comes with its own specifications on how to use it, but I have shared a basic guide on how to use one.

Here are the steps to follow when using an air compressor:

Step 1: Plug in Power

You need to start by pacing the air compressor on a solid and even work area. Check to confirm that the power switch is off and then connect to the power source. Please plug it in into a grounded power outlet.

Step 2: Check Oil Level

Check the oil level, especially if you have a piston-type air compressor. You can check through the sight gauge, which is usually at the bottom of the compressor motor, in most models. If the oil is not up to the recommended level, fill it up. Make it a habit to check the oil level after every use.

Step 3: Fill up the Air Tank

The bottom of the air tank drain valve is Close. Use an adjustable wrench to turn the valve in a clockwise direction. Now, turn on the power switch and allow your compressor to run for a couple of minutes.

Check the air gauge and be sure that the compressor will automatically shut off when the pressure gets to the maximum PSI. The pressure capacity may vary depending on the model that you have.

Step 4: Air Control Valve Adjustment

Make adjustments to the air control valve. This should match to the air tool that you want to use. Turn the air control valve in either direction until the pressure gauge the right air pressure for the specific tool.

Step 5: Connect the Hose

Now, connect the air hose to the compressor. Ensure that you have a hose that is long enough to get to your work area. It is advisable to wrap the threaded end of the hose with Teflon tape.

Thread the hose onto the compressor fitting, which is near the air pressure gauge. Use an adjustable wrench to tighten it in the clockwise direction.

Step 6: Connect the Air Tool

On the other end of the hose, connect the pneumatic tool. Most models have a quick connect fitting to aid this step. Just pull back the collar of the hose, which is spring-loaded, and push it into the tool. Release the collar and this will secure the connection of the air tool and the hose.

When you need to disconnect the pneumatic tool, just pull back the collar, while pulling the tool off.

Step 7: Drain Moisture

When you are done using your air compressor, be sure to drain the moisture from the air tank. Loosen and remove the drain valve, with an adjustable wrench. Turn it in the counterclockwise direction and when all the water is drained, replace the valve and tighten it.

How Reliable Are 60 Gallon Air Compressors?

Yes, 60 Gallon Air Compressors are more reliable than other gallons of air compressors. It depends on you. Let me explain the point shortly.

- Firstly, it will solely depend on the machine with which you will use it. If the air compressor is compatible with the core unit and accepts 60-gallon type, it is highly reliable.

- Among the different air compressors, 60-gallon air compressors are widely used worldwide because of their versatility and durability.

- Due to super fuel efficiency, I personally trust the 60-gallon air compressor among different types of air compressors.

- Lastly, people’s choices vary, depending on the model you have purchased and how comfortable you use it. The more you spend money on buying air compressors, the better you will get- it is not the real thing. You can choose any of the 60-gallon air compressors that I have mentioned above!

FAQs

#1. Does the air compressor come with oil?

Hardly will your air compressor come with oil to use. You can buy oil from the supplies store. Be sure to confirm which type of oil it uses.

#2. Can I use a generator to run an air compressor?

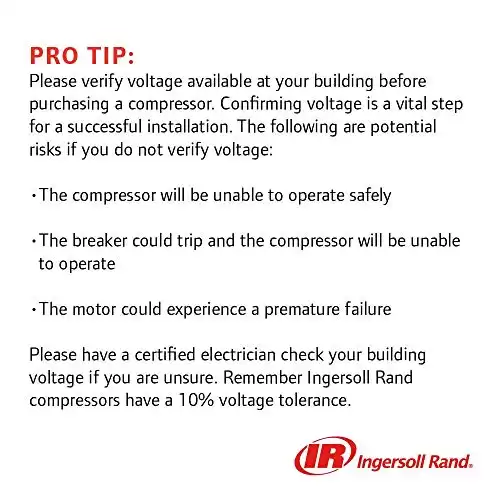

There should be no problem running the compressor off a generator. However, you need to ensure that the generator has adequate power that matches the voltage of the air compressor.

#3. How Do I Control the Output Pressure on my air compressor?

Most models will come with a dial that will be used to limit the output pressure from the compressor. If your model does not have a dial, you can use a regulator on the outlet hose.

#4. What are the noise levels of a 60-gallon air compressor?

The noise levels will vary from model to model. The number of cylinders tends to influence the noise levels and this is why most three-cylinder compressors are rather loud.

#5. What type of oil will the air compressor use?

There is specific oil that is sold in the stores for compressors. It is best to check the manufacturer’s recommendation for the same.

#6. Who makes the most reliable 60-gallon air compressor?

It is difficult to say who makes the most reliable 60-gallon air compressor because after using any of the air compressors, you will know about the most reliable air compressors for you.

You can choose any one of the 60-gallon air compressors that I elaborately described above. Four of the air compressors I have written about are almost suitable and reliable for you! Before buying air compressors, you should know the types and what purposes you are buying.

#7. Which brand of air compressor is best?

There are many different types of air compressors. So it can be challenging to decide the best air compressors because new, well-designed air compressors are popping up as the days pass. If I need to choose some of the best brands of air compressors, I would suggest you prefer them although they are pretty pricey.

- Briggs and Stratton

- Quincy

#8. Can a 60 Gallon compressor be used outdoors?

A 60 Gallon compressor is generally used indoors, but you can use it outdoors, maintaining proper instructions authorized by the company or manufacturers. But the problem is they can not keep in rain, snow, winds, excessive cold, and heat. It will be damaged if something goes wrong.

Final Thoughts

Purchasing an air compressor is not something that you should do in a hurry. It may be tempting to choose the cheapest product on the market, but this should not be the case.

With this guide, you will realize that it takes more than a price to find the best 60 gallon air compressor. The models I have reviewed are some of the best, and I hope they will help you to make the right purchasing decision.

Myself Erick R. Jackson, I am a Computer Science graduate by law but a passionately enchanted blogger by profession.

A few years back, it all started with my first blog website. It was about to deal and heal with automotive hand tools. Well, it brought me a good audience base for sure, which then dragged me out of my major and got me to sit and write, and be a blogger. Read more