The ball joints in vehicles are spherical beams that are important to your steering system. They connect the control arms of your vehicle to the steering knuckles.

Greasing your ball joints aids the longevity and better performance of your steering system. Today, we shall talk about the greasing procedure of ball joints in your vehicle.

Let’s get our feet wet in the process.

Related Read : Best Grease For Ball Joints

Types of Grease Ball Joints

Ball joints mainly come in two types;

- Ball joints without jerk fittings

- Ball joints with jerk fittings

List of Tools You Will Need

1. Grease

2. Grease Gun

This is a physically controlled oil firearm that will give you a chance to settle on how much oil goes into the tie bar, and after that, it can tell you when it is getting full.

It is advisable that you use a manual grease gun for ball joints without jerk fittings and a hand powered grease gun for ball joints with grease fittings.

The manual grease gun will give you the power to control the quantity of grease that goes in and allow you to know the resistance of the ball joint during the process of greasing it.

On the other side, a hand-powered gun will apply less pressure to the seal of the ball joint and also let you know how much grease the ball joints are getting.

3. Flexible Hose

It is excruciating some of the time doing fragile work under your vehicle, yet a hose can give you considerably more flexibility when endeavoring to get the needle into the residue boot.

4. Rag or Cloth

This is utilized for cleaning the jerk and wiping ceaselessly abundance oil which is a vital piece of the procedure.

5. Oil Jerk Needle (for ball joints with jerk fittings)

An oil jerk needle connector that will likewise require a needle fitted with an oil jerk that can enter the residue boot and present oil inside the tie bar.

Try to grease your ball joints as frequently as you can.

Steps In Greasing Your Ball Joints: Ball Joints Without Jerk Fitting

Here, we go step by step to under go the greasing formalities for ball joints without jerk fitting below.

1. Check The Boot

In the event that it is torn or missing, then it is wearing the part out and setting it up to bomb soon. You will need to replace the boot since debases may as have now been inside the smooth metal innards.

2. Cleaning The Boot And Joint

This is exceedingly required to clean the boot more as a man can perceive what is happening when you start drawing oil into it.

3. Attach The Jerk Needle Adapter To The Grease Gun

Be very careful when doing this:

- Loosen the coupler

- Snap the needle into the coupler

- Tighten the coupler

- Remove the plastic cap

- When you are done, reattach the plastic cap

4. Fixing The Connector Once The Needle Is On

Make sure to tighten the adapter/connector once the needle is on or the oil will overflow out from between the needle and oil firearm without making it to the joint. Next, append the jerk needle connector to the oil firearm.

5. Pump Gradually Until The Point That The Boot Starts To Swell

A few people say that you should keep lubing your auto until the point that you see oil overflow around the boot yet keeping up that seal is critical, so we settle on the more secure course.

Ensure that you can watch to clean boot while you are pumping the oil, this is on the grounds that once it starts to swell, you are done and pumping past this point could make harm the seal.

Embedding The Needle Into The Side Of The Boot: You will likewise need to do this training with the goal that new oil has a superior possibility of getting into the bearing.

6. Expel The Needle And Wipe Off Any Abundance Oil

It is important that there won’t be much if any overabundance oil in the needle – even in the event when there is proper wiping it down – will shield the residue, flotsam and jetsam from gathering on that additional oil around the joint.

This henceforth permits a snappier finding of future issues.

7. Take The Vehicle Around The Square

Once you’re back in the carport, you should investigate those wiped down joints and check whether there is any oil spillage. However, in the event that everything looks and sounds altogether, then congrats! At that point, you’ve quite recently lubed the un-graspable.

Steps In Greasing Your Ball Joints: Ball Joints With Jerk Fitting

Now that you have learnt the greasing procedure for ball joints with jerk fitting, it will be an added convenience to learn about the one without jerk fitting. Here we go below!

On the off chance that your vehicle’s tie-pole closes accompanied an oil jerk fitting introduced, the way towards lubing is extremely basic.

1. You Ought To Investigate The Residue Boot

Supplant the residue boot in the event that you discover an issue since a tear implies your oil will spill and pollute could enter the boot.

And the smooth surface of the ball will start to wear prompting disappointment.

2. Utilize The Cloth To Clean The Jerk

It is fundamental to clean the jerk where if the jerk is rusted or eroded past straightforward cloth cleaning, you can utilize something more grounded or supplant the oil to zero.

3. Connect The Oil Firearm To The Jerk

You likewise need to simply make sure to fix it before pumping. You will be required to position the spout solidly finished and press down until the point when you feel the spout getting the jerk.

4. Watch The Residue Boot And Give The Oil Firearm A Couple Of Good Pumps Until The Point When You See The Boot Start To Swell

This is the best alternative not to continue lubing, once you see the boot swell. Because seal that holds that oil in the tie pole end can be endangered if a lot of weight is connected. Subsequently, you are expected to guarantee a visit lubing.

5. Rotating Appendages Have An Oil Help Valve

These valves have their own significance in that they enable old oil to securely leave the swivelling appendage without trading off the seal.

6. Clean Any Overabundance Oil From The Jerk And Residue Boot

In the event that you ever see that your controlling wheel is free and unsteady, at that point, your tie pole end is probably going to encounter a disappointment or even they have bombed as of now and ought to be supplanted.

Finish the steps by driving the auto around the square and check for any spillage. On the off chance that you have a settled and dependable drive or hit the trails on the end of the week, take your vehicle out on some comparable territory before checking the tie pole end.

Frequently Asked Questions

As the greasing process is admittedly a tough task to do, it is obvious that you might have some questions in mind. So we will end the article answering some important and commonly asked queries.

1. How regularly would it be advisable for me to oil my oil capable jerk fitting?

You are expected to comprehend that you can’t get over oil an oil capable jerk fitting. You ought to dependably keep it grease able since graspable jerk fitting ought to be lubed after every 3000 miles or more.

2. How would I oil my Tie Rod Ends?

The vast majority of these tie bar closes generally accompany an oil jerk fitting that is introduced, and some are fixed from the manufacturing plant with no simple road for oil.

3. How would I oil my swivelling appendages?

A large portion of the rotating appendages has oil jerk fittings which influence the oil to process a great deal and lesser demanding.

Yet a few people additionally need to add a little oil to the fixed, stock swivelling appendages on their vehicles that don’t have jerks.

This way, they will spread out nitty gritty directions for lubing fixed rotating conjunctures and those that have jerk fittings.

4. How would you do oil if there is no oil jerk fitting?

Fixed tie-bar closes originate from the production line with adequate oil and are secured tight to keep sullies out.

However, in the event that you need to revive the oil in your tie-bar closes, you can utilize an oil weapon needle connection to move beyond the residue boot and draw some oil into that part.

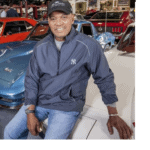

Myself Erick R. Jackson, I am a Computer Science graduate by law but a passionately enchanted blogger by profession.

A few years back, it all started with my first blog website. It was about to deal and heal with automotive hand tools. Well, it brought me a good audience base for sure, which then dragged me out of my major and got me to sit and write, and be a blogger. Read more